|

제목

|

♣ “TC-ER” Tray Cable Rating.

|

|

작성일자

|

2021-02-01

|

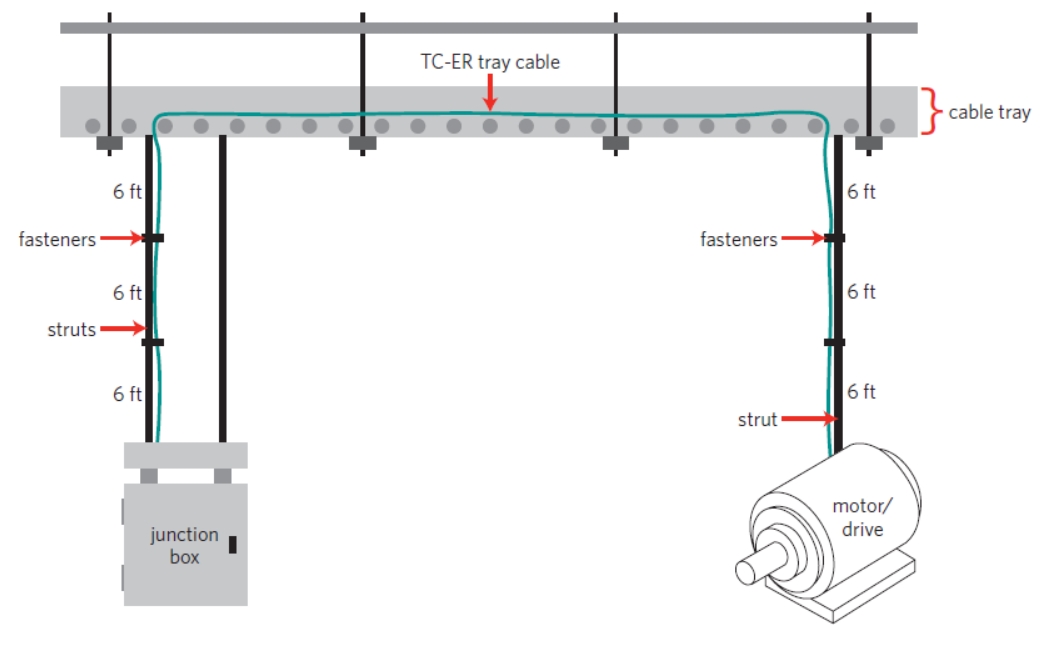

“TC-ER” Tray Cable Rating.What is an ER Rating?In the 1990s, an “ER” rating for unarmored, physically rugged instrumentation and control tray cableswas made possible by changes in NEC1 and UL2 requirements. The “-ER” suffix stands for “ExposedRun.” The rating was created for type “TC” tray cables, type “ITC” instrumentation tray cables, andfor type “PLTC” power limited tray cables. If these UL cable types meet certain additional crush andimpact test requirements, UL permits the manufacturer to add an “-ER” suffix to the basic listingprinted on the cable, i.e., TC-ER, ITC-ER, or PLTC-ER. The “-ER” signifies that the cable is sufficientlyrugged to permit its use as exposed wiring. Exposed wiring is wiring that is not installed in a tray,conduit or other raceway. Exposed run cables were formerly referred to as Open Wiring, and printedwith the words, “Open Wiring” instead of the “-ER” suffix. Some people still use the term “OpenWiring” today. Simply be aware that this is synonymous with TC-ER. Similarly, some people may usethe following terms: Exposed Reach, Extended Reach, or Extended Run.What are the Benefits of Having ER Rated Cables?Tray cable types TC, ITC and PLTC are permitted in cable trays by the NEC. However, if more than 1.8meters (6 ft) of cable extends from the tray for a connection to a motor or other electrical device,cables without an ER rating must be either armored (type MC) or installed in conduit or another typeof raceway. On the contrary, cables with an ER rating can extend up to 50 feet outside the tray if givenadequate protection and support. Thus, in some applications, the use of ER rated cables can eliminatethe cost of installing conduit between the tray and an electrical device or the cost of using armoredcables. The electrical specifying engineer has the opportunity to value-engineer a project simply byspecifying ER rated tray cable, and potentially generating substantial cost savings in the process. “TC-ER” Tray Cable Rating.What is an ER Rating?In the 1990s, an “ER” rating for unarmored, physically rugged instrumentation and control tray cableswas made possible by changes in NEC1 and UL2 requirements. The “-ER” suffix stands for “ExposedRun.” The rating was created for type “TC” tray cables, type “ITC” instrumentation tray cables, andfor type “PLTC” power limited tray cables. If these UL cable types meet certain additional crush andimpact test requirements, UL permits the manufacturer to add an “-ER” suffix to the basic listingprinted on the cable, i.e., TC-ER, ITC-ER, or PLTC-ER. The “-ER” signifies that the cable is sufficientlyrugged to permit its use as exposed wiring. Exposed wiring is wiring that is not installed in a tray,conduit or other raceway. Exposed run cables were formerly referred to as Open Wiring, and printedwith the words, “Open Wiring” instead of the “-ER” suffix. Some people still use the term “OpenWiring” today. Simply be aware that this is synonymous with TC-ER. Similarly, some people may usethe following terms: Exposed Reach, Extended Reach, or Extended Run.What are the Benefits of Having ER Rated Cables?Tray cable types TC, ITC and PLTC are permitted in cable trays by the NEC. However, if more than 1.8meters (6 ft) of cable extends from the tray for a connection to a motor or other electrical device,cables without an ER rating must be either armored (type MC) or installed in conduit or another typeof raceway. On the contrary, cables with an ER rating can extend up to 50 feet outside the tray if givenadequate protection and support. Thus, in some applications, the use of ER rated cables can eliminatethe cost of installing conduit between the tray and an electrical device or the cost of using armoredcables. The electrical specifying engineer has the opportunity to value-engineer a project simply byspecifying ER rated tray cable, and potentially generating substantial cost savings in the process. Cable Jacket Print LegendThe jacket of ER rated tray cables must be printed with the letters “TC-ER,” “ITC-ER,” or “PLTC-ER” asappropriate for the specific cable. Industry codes and standards require the markings so the electricalinspector at a job site can confirm that the cable meets applicable requirements.Grounding Conductor RequirementsWith TC-ER cables, the NEC requires that an equipment grounding conductor be provided withinthe cable (2005 NEC Article 336.10(7)). However, in 6 AWG and smaller cables, any insulatedconductor in the cable is permitted to be identified as the equipment grounding conductor at the timeof installation. This can be accomplished by stripping the insulation from the entire exposed length,coloring the exposed insulation green, or marking the exposed insulation with green tape or greenlabels (2005 NEC Article 250.119(B)). Cable types ITC-ER and PLTC-ER are not required to have anequipment grounding conductor (2005 NEC Articles 725.2 and727.2).Additional RequirementsThe NEC has several additional requirements that must also be met before ER rated cables can beused in exposed runs.• Exposed runs are permitted only in industrial establishments where the conditions ofmaintenance and supervision ensure that qualified persons service the installation.• The exposed run must be between a cable tray and equipment such as a motor.• Type ITC cables are limited to 15.2m (50 ft) in length between tray and equipment. Types TC andPLTC cable have no length restrictions.• Cables must be supported and protected against physical damage using mechanical protectionsuch as struts, angles, or channels.• Cables must be secured at least every 1.8 m (6 ft). Cable Jacket Print LegendThe jacket of ER rated tray cables must be printed with the letters “TC-ER,” “ITC-ER,” or “PLTC-ER” asappropriate for the specific cable. Industry codes and standards require the markings so the electricalinspector at a job site can confirm that the cable meets applicable requirements.Grounding Conductor RequirementsWith TC-ER cables, the NEC requires that an equipment grounding conductor be provided withinthe cable (2005 NEC Article 336.10(7)). However, in 6 AWG and smaller cables, any insulatedconductor in the cable is permitted to be identified as the equipment grounding conductor at the timeof installation. This can be accomplished by stripping the insulation from the entire exposed length,coloring the exposed insulation green, or marking the exposed insulation with green tape or greenlabels (2005 NEC Article 250.119(B)). Cable types ITC-ER and PLTC-ER are not required to have anequipment grounding conductor (2005 NEC Articles 725.2 and727.2).Additional RequirementsThe NEC has several additional requirements that must also be met before ER rated cables can beused in exposed runs.• Exposed runs are permitted only in industrial establishments where the conditions ofmaintenance and supervision ensure that qualified persons service the installation.• The exposed run must be between a cable tray and equipment such as a motor.• Type ITC cables are limited to 15.2m (50 ft) in length between tray and equipment. Types TC andPLTC cable have no length restrictions.• Cables must be supported and protected against physical damage using mechanical protectionsuch as struts, angles, or channels.• Cables must be secured at least every 1.8 m (6 ft).

|

|

첨부파일

|

|

|

|

|

|